|

The mounting and installation of this sensor needs special attention. Technocarb recommends that it be mounted away from heat, vibration and weather. The hoses which attach to the pressure and vacuum ports needs to be supported so that there is no weight and movement at the ports. With that I found a nice mount area between the battery and headlight that would fulfill the requirements. |

Paper template cutouts were used to transfer the bracket shapes to metal. The metal was cut, ground and belt sanded.

Here are the pieces with the sensor. |

A little fit up to determine where the sensor would be mounted and we are ready for welding. |

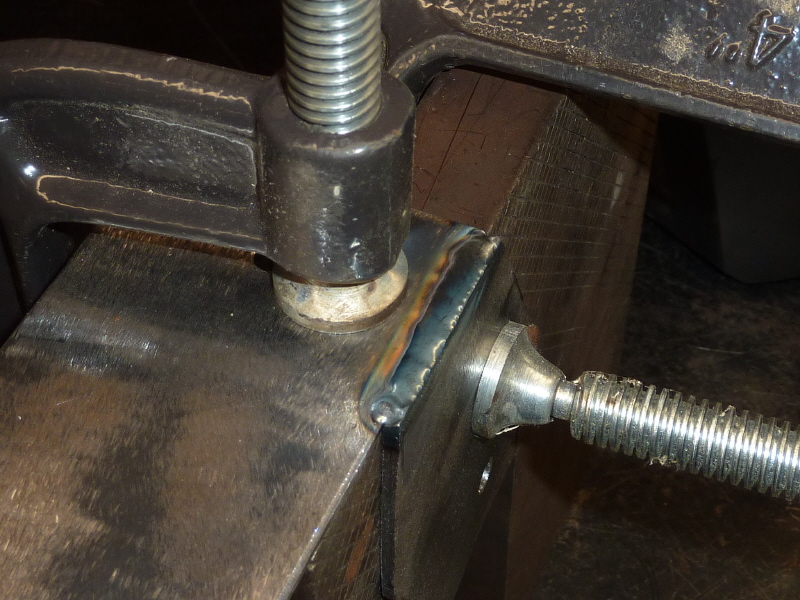

Here the pieces are clamped to an iron plate to assure a 90° angle between the two pieces. |

With the bracket clamped, a single TIG weld pass was made. Notice how the weld looks like liquid glass. |

The bracket was then flipped over and a fillet weld applied to the other side. A threaded stud was welded into a hole to provide the sensor an anchor point. |

The bracket is then prepped and 3 coats of satin black enamel are applied. Once dried the sensor is attached and a nylon lock nut is tightened. |

Here a small block was fabricated attached to the bracket. 8 holes were drilled and zip ties added to secure the hoses. This should provide the stability needed to prevent damage. |

The electrical connection plug and harness are prepped and readied for installation. |

Here everything is connected and ready to be installed into the protected location. |

This is a pic of the installed assembly. |

Another pic, another angle. |