|

As you already know, the CNG tanks I am using came from salvaged Cavaliers. The HPL (High Pressure Lockoff), which screws into the end of the tank, comes from GFI Teleflex. GFI makes different spin-offs of their HPL. The one used in a Cavalier has a built in temperature sensor and an extra port for a pressure sensor. I found that the Ford F250 version only has 3 ports, not 4 and no temperature sensor. I purchased 4 of them off Ebay. Unfortunately I found out that the PRD (Pressure Relief Device) port has a left hand 9/16" thread and the Cavalier version does not.

|

Here is a pic of the Ford version, I am using. It has two inlet ports and the PDR port, located to the lower right of the black power connector. So I began my search for a Parker fitting in left hand thread only to find that it is OEM. The Ford dealer indicated that the filling comes with the HPL. |

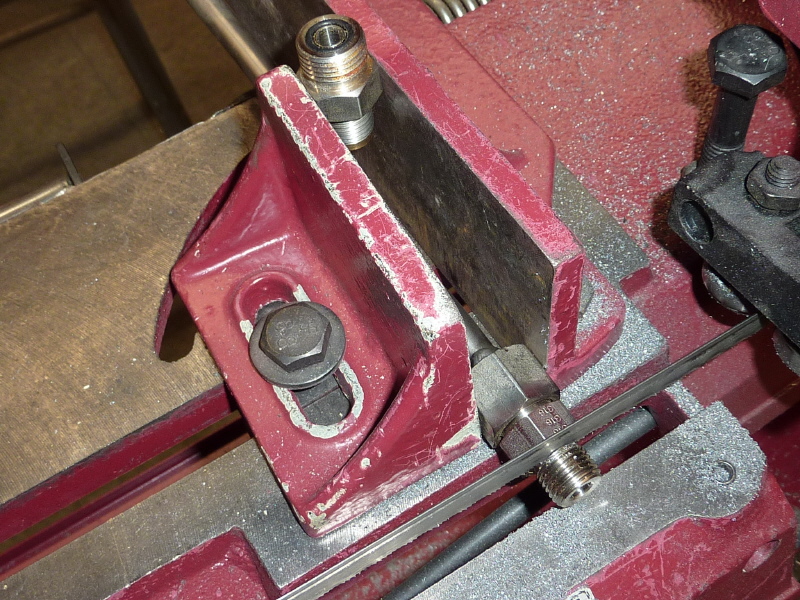

So I just decided to make one, ya that right, just make one. The first order of business was to get a stainless bolt and lathe off the head. Then cut it down to the Major Diameter of the 9/16" thread.

|

Next I needed to drill the port hole for the gas to vent through. |

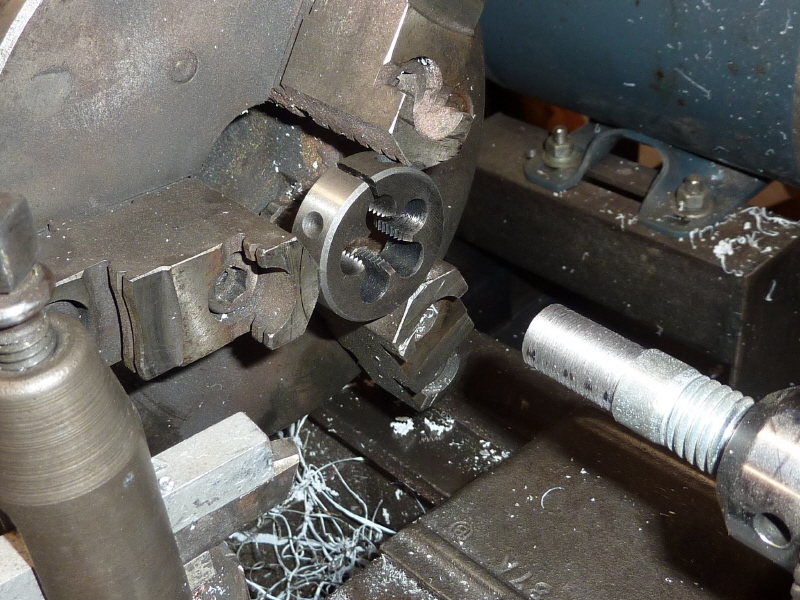

Here is a pic of the 9/16" x 18 UNC (LH) die. It was difficult finding one at a reasonable cost. |

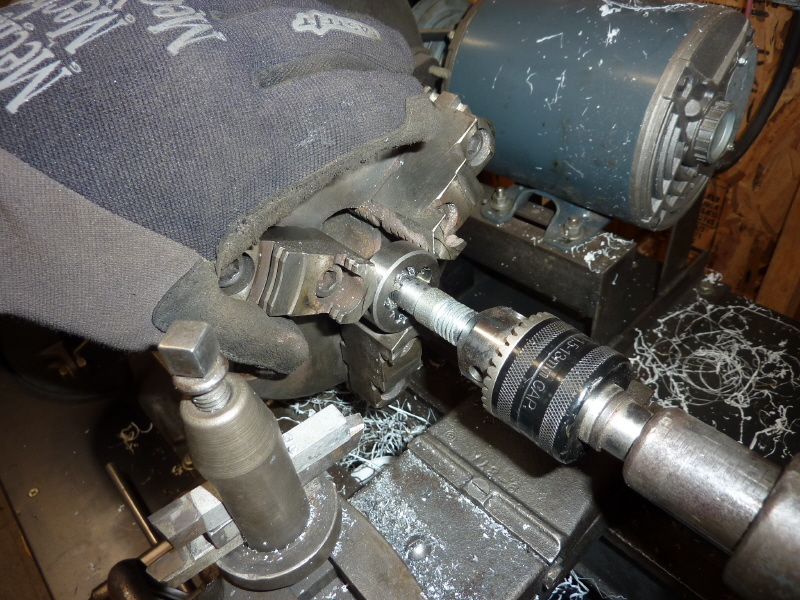

With the die chucked in the lathe, it was time to cut threads. |

I left the tail stock a little loose so it could be drawn in as the die advanced down the stock.

|

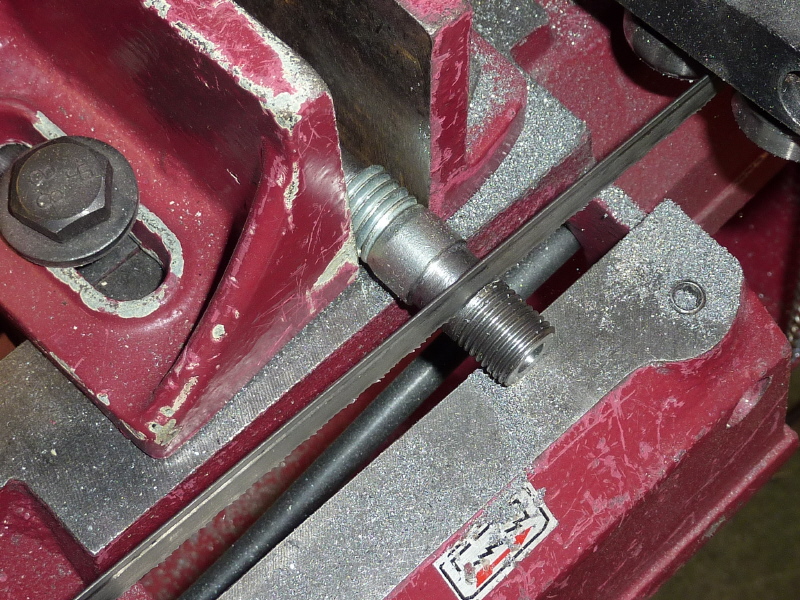

Here is all the thread I need. A little cleanup and buff on the wire wheel and we are done. |

This is the PDR fitting from an old Cavalier HPL. I sawed off the right hand threads which left me with the hex end.

|

Here I am sawing off the left hand threads from the previous machining. |

I used a bolt to clamp the two pieces together while I TIG welded the little assembly.

|

When complete, I had to lathe a little weld away and chase the threads a bit to get a clean fit in the HPL. |

Another pic of the fitting ready to be installed into the HPL.

|

I realized from the start that this fitting will only see pressure on discharge only. So I decided to use Teflon tape on the threads instead of monkeying around with an O-ring seal. It works for me. |