|

The splice and wiring of the gasoline fuel injectors was an daunting task. I had received a wiring diagram for a LNG system which is different than a CNG system. Add in that all the wires are different colors, none match up color to color, the 2 harnesses have more wires that connections. I could go on, however lets look at the task at hand.

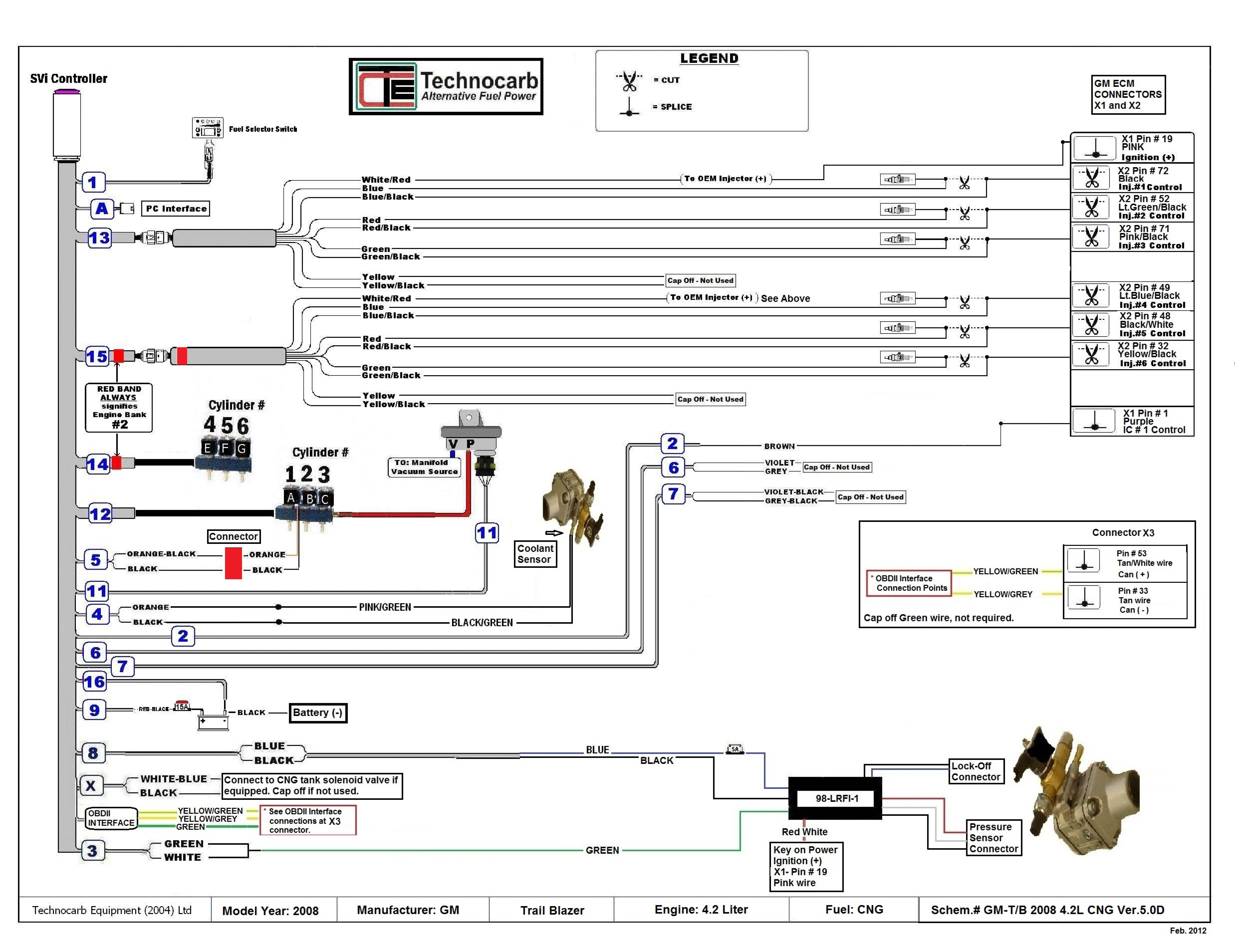

You will need to make sure that the Technocarb wiring diagram is correct for your application. You then need to verify wire colors against diagrams and obtained information to verify your OEM wire configuration. |

This is the latest Technocarb wiring diagram for my Trailblazer. |

This is a GM fuel injector schematic. It shows the injector positions and their wire colors. You can use this to check the Technocarb wiring diagram. |

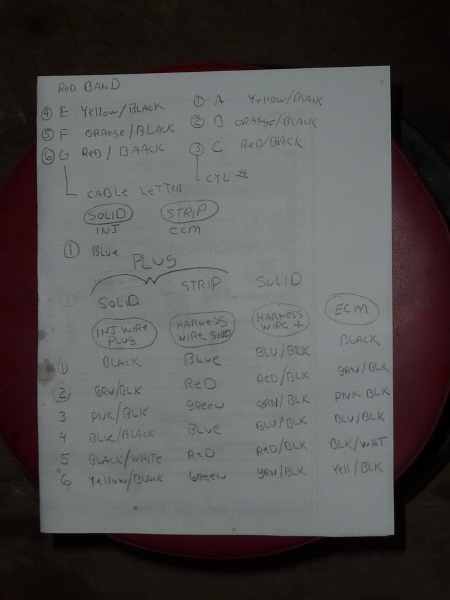

I then generated this wire connection chart. Doing this stuff will make you intimately familiar with the wiring task. |

After removing the intake air plenum, the injector wire connector (X104) is visible. Remove the white safety clip and pull the connector apart. |

In order to get to the injector wires, you need to cut and peel back the wrapped cover tape. This will expose the wires. |

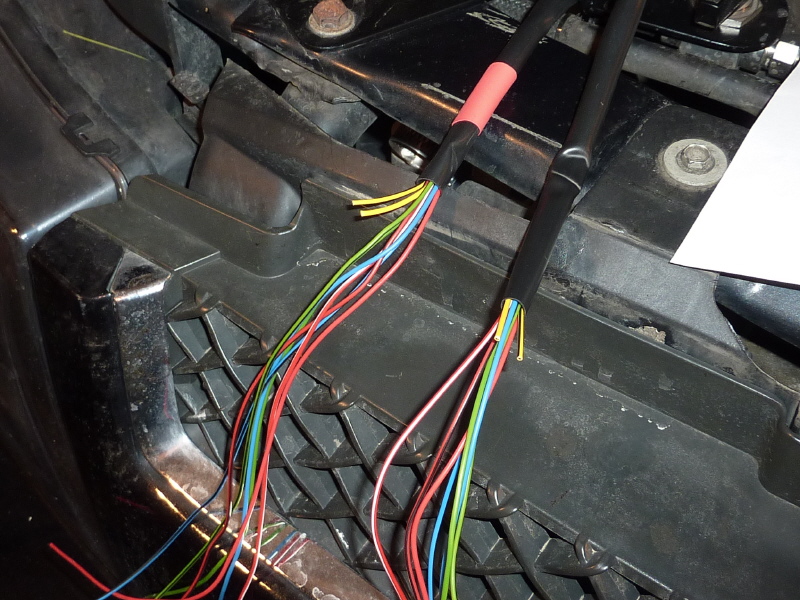

Get your favorite cutting pliers and just cut the cable in half. Make sure you leave enough wire lead to make your splices. |

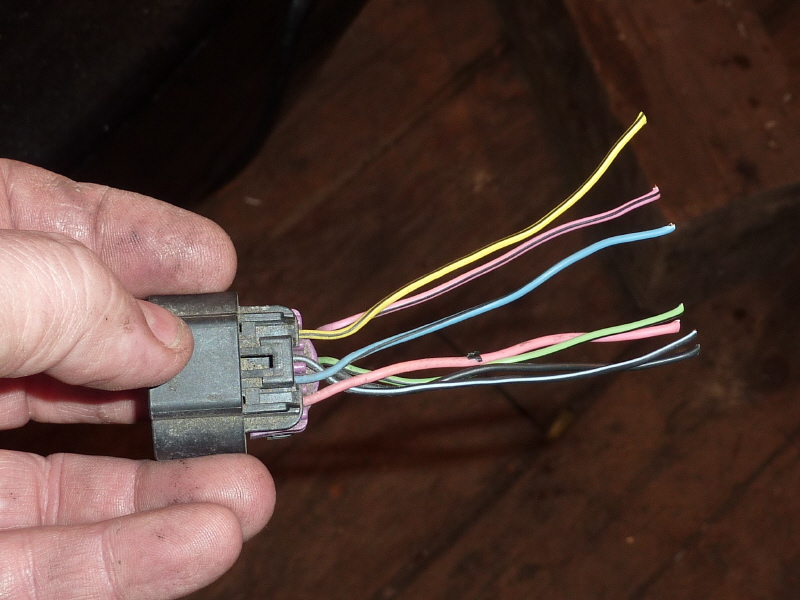

The wires contained in each harness are the exact same colors and there are more wires than connections. |

So you need to cut the yellow and yellow/black wires from each harness to give you 6 connects for 6 cylinders. |

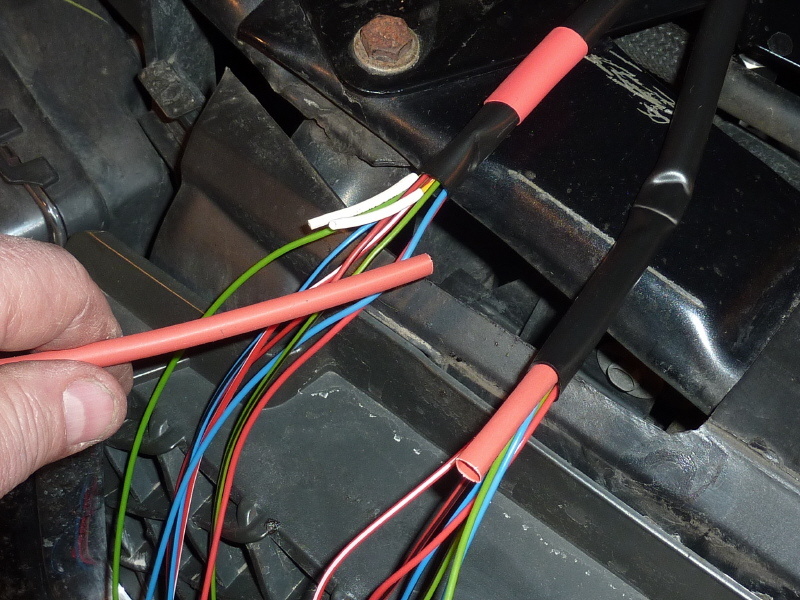

Once the extra wires are cut, they need to be capped. I capped each individual wire (white) then capped both together (red). |

This is a typical connection. I slide a piece of shrink tubing on one wire leg. Then solder tint each wire. A metal sleeve is then slipped over each wire and crimped. The shrink tubing is positioned and heat applied. |

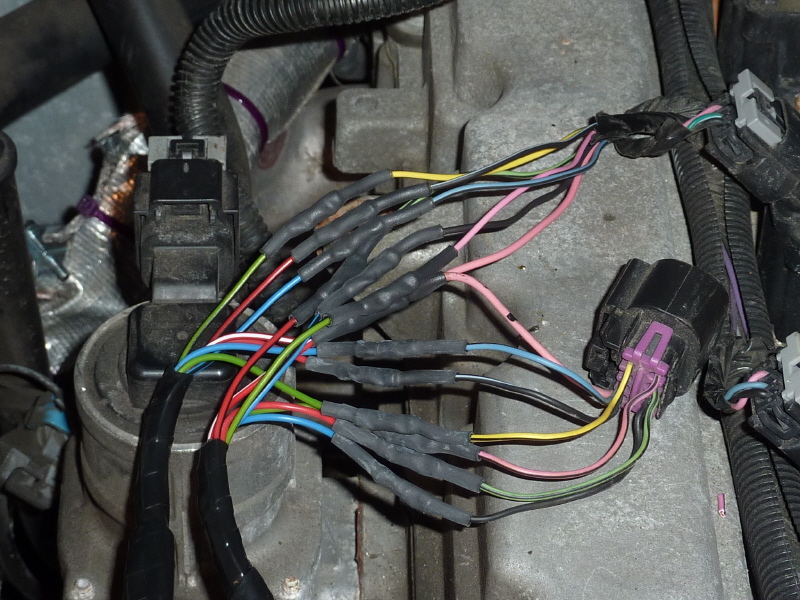

Here all the negative wires from the Technocarb ECM are spliced into the connector leads. That's right negative, the negative wires are wired to the fuel injectors as if they are positive and the positive wires are all connected together like ground. It's the dammedist thing I ever seen. |

Here the Trailblazer ECM's negative wires are readied to be spliced. Now you see why I have a connector diagram. |

With all the injector wires spliced and insolated, I rolled the wire bundles and wrapped each one in electrical tape. |

Wire loom was added to each harness, the harness routed and the air plenum replaced. |

This job is probably the first time in my life that I triple checked my work. So intent war I on getting this right I spent a ton of study, prep and wiring time. In the end it paid off. |