|

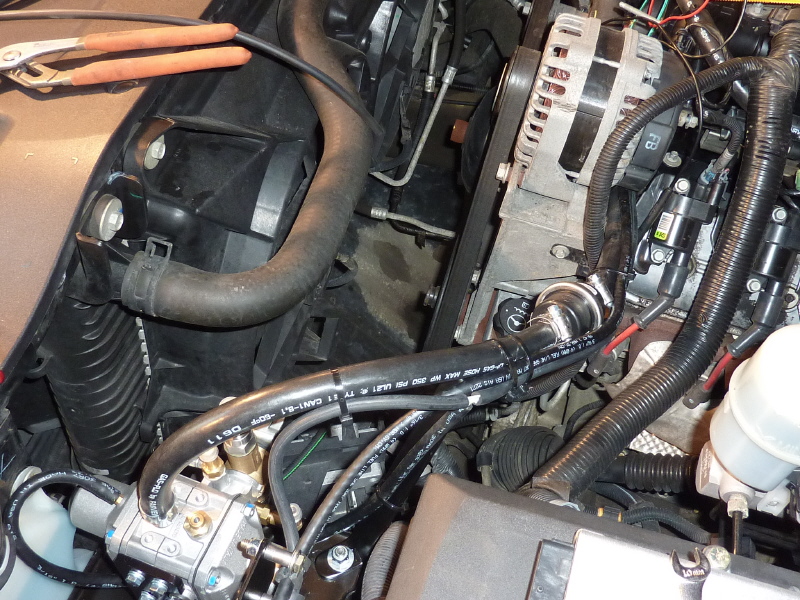

A problem I noticed was the long distance the rail injector supply hose had to travel, unsupported from the alternator to the CNG regulator. A support bracket would need to be fabricated to protect the hose. |

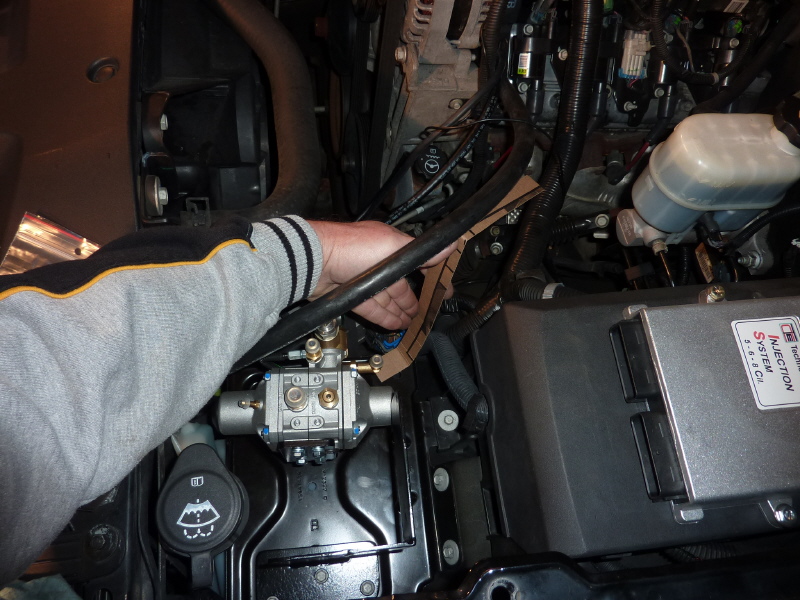

Here I am sizing up a bracket template made from cardboard. Once the template is finalized, it will be transferred to steel.

|

With that I chucked up a piece of 1" x 1/4" bar in the electric band saw and cut to size. |

A 5 pound sledge is used to pound the end flanges to the correct angles. A couple of trips to the engine compartment was needed to check the angles, fit and clearance.

|

The mount hole is drilled, de-bured and chamfered.

|

A quick trip to the sand blasting booth prepares the bracket for 3 coats of satin Rustoleum. |

The finished bracket is mounted and bolted down.

|

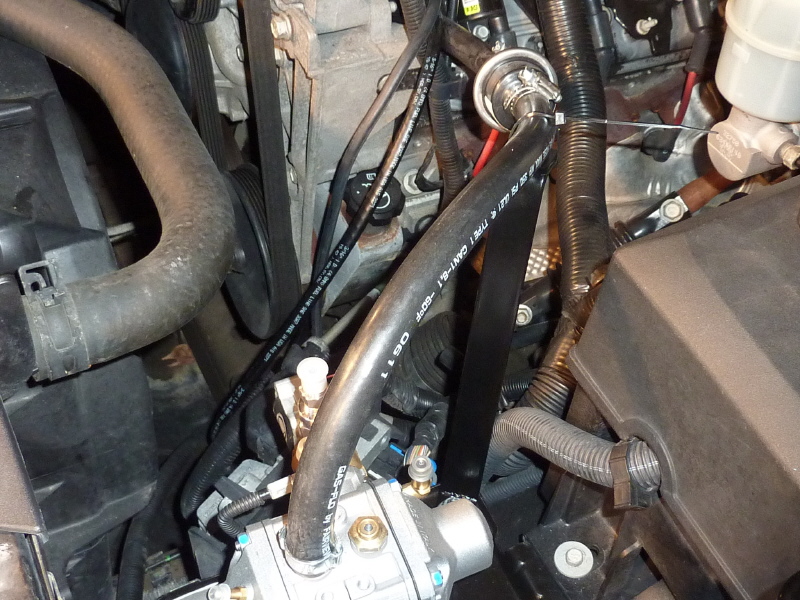

The rail injector supply hose is fitted and clamped to the CNG regulator. |

Zip ties are used to hold the CNG supply hose to the support bracket top flange. This will supply the proper support for the 1" diameter hose. |

This is a view looking down on the bracket and supply hose. |

Another view from a different angle.

|

I used gear clamps on the fuel filter to make it easy to replace. To remove an Oetiker clamp requires cutting it off and you do not want to got there. |