|

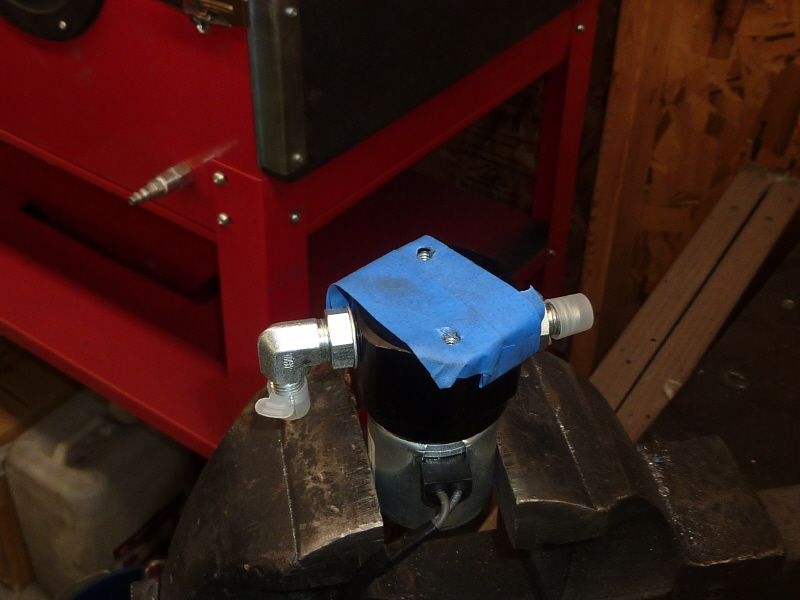

Since the SCI Type 3 tanks, I am using, only have a manual shutoff, I decided to add an electric solenoid valve.

The reason for this is to contain the high pressure, from the tanks, to the smallest amount of tubing. With a check valve screwed into the first tank, a transfer tube from tank to tank and the solenoid valve connected to the second tank, high pressure gas is trapped in a small amount of tube. |

To get started, this is a salvaged bracket from a Cavalier. It transitions the angler tank bracket to horizontal for bolting. Once the bottom is sawed off, it will provide the proper angle for welding my solenoid bracket

|

Here we begin the process of sawing metal. I have found that 1/4" thick bar makes more ridged brackets than 1/8" bar.

So I have switched to the thicker bar for critical brackets. |

There will be two angler pieces that will bolt to the tank bracket.

Here the mounting hole is being drilled. |

These are the three pieces that will form the bracket base. The metric screws used were the same ones that held the sawed apart transitional piece on.

|

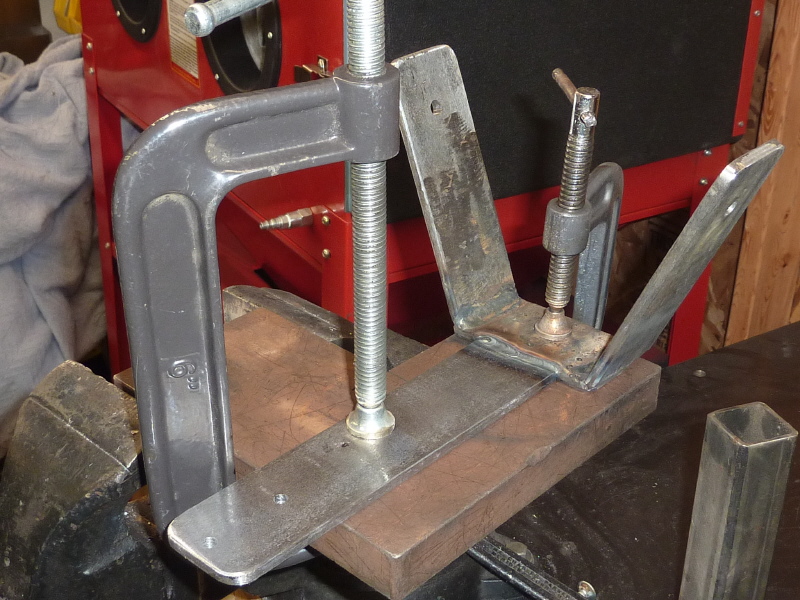

Here the transitional piece is used as a welding template to obtain the proper angle of one side. The assembly is clamped and TIG welded. |

After I realized that there would be minimum success jigging the angle correctly to fit, I bit the bullet and bolted the bracket in place for welding.

|

There is an element of collateral damage when welding directly on a vehicle. However once welded and cooled, the bracket now fits perfectly. |

Before I weld the final piece of the bracket on, I decided to weld the other side of the bracket. |

I think the weld was overkill, however it makes the bracket more ridged. |

This is the final piece being fitted for the solenoid valve to bolt to. |

A quick masking tape transfer template will give me the proper hole locations on the bracket. |

The holes are transferred, drilled and chamfered. |

Here the final piece is clamped and TIG welded. |

I sand blasted the bracket, however decided to make a sanity fit up before I spend the time painting the bracket only to find I missed something. |

After painting, another bulkhead fitting needs installed. I am using silicon rubber to seal out moisture so the floor does not rust. |

Prep-Sol works OK for cleanup, however lacquer thinner is way better.

|

Once the bulkhead fitting and solenoid are installed, a piece of 1/4" tubing needs bent and fitted. I am using a 3" PVC pipe end for the relief loop diameter. |

This is the final fit up and clearance check. All is well.

|

The AFC High-Pressure CNG Valve was a real steal. I got it in an Ebay auction for $35.00. Thank god for Ebay. |