|

The wiring of the 98 GMFSCI was not a real easy task. Everything had to be done from your back including soldering. Any time you are soldering from your back or upside down, bad things usually happen. I got hit once with a soldering iron and have a scar to show for it. On a good note I was able to avoid solder spatter. The interface mount was fabricated and installed in a different post. So that will not be covered here. |

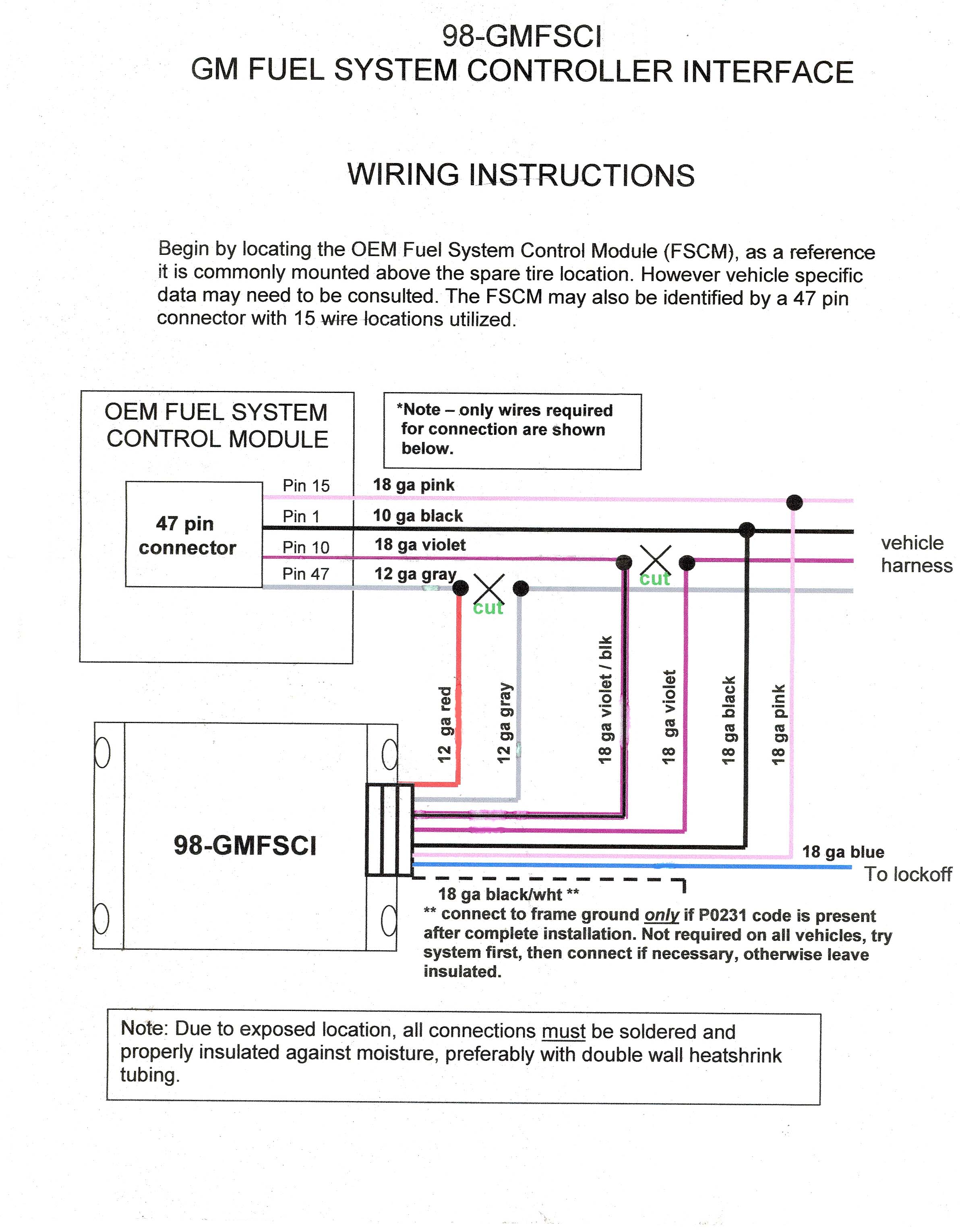

This is the wiring diagram that I worked from. You will also need the fuel pressure module connector pin outs which are located here. |

|

The first thing you need to do is unlock the connector and pull it out. You will need to clean the seal areas and rub on some Vaseline before re-connecting it. |

I started out by attacking the easy connections. |

|

Here I am probing for the ignition voltage wire using a volt /ohm meter and some strait pins. |

Once located, the connection is made |

|

More and more connections are made and the loose wires have just about disappeared. |

Once all the connections are made, plastic wire loom is applied and the end are secured with electrical tape. |

|

It is important to use a quality electrical tape. One that will hold up to temperature and harsh environmental conditions. I suggest Scotch Super Vinyl Electrical Tape 88. |

This is a view of the 98 GMFSCI mounted and the wires nicely routed in plastic wire loom. |

|

This is a view of the fuel pressure module connector re-connected and its wires routed. |

One thing I noticed was the wire bundle rubbed hard against the pressure module mount. I cut a piece of rubber fuel line and slid it over the edge of the mount. |

|

The next job at hand is to connect switched power to the CNG solenoid mounted at the tanks. Above is a Greenlee Radio chassis punch. I have used these punches since I was a teenager. They will punch a perfectly round hole with no metal disfigurement. |

Once a pilot hole is drilled, you insert the punch and crank away until you here a tink. |

|

This is what a precision punched hole looks like. I have punched 1/8" aluminum panel with these and had no problems. |

A nice rubber grommet is inserted into the hole to protect the incoming power wire.. |

|

I am using a two wire connector salvaged from a Cavalier to make a water tight connection. Some zip ties make the job nice and neat. |

Unfortunately I had to remove the spare tire. The system GM uses to mount the spare tire stinks. At a later date, I will design a better reusable tire mount instead of the OEM piece of junk. |