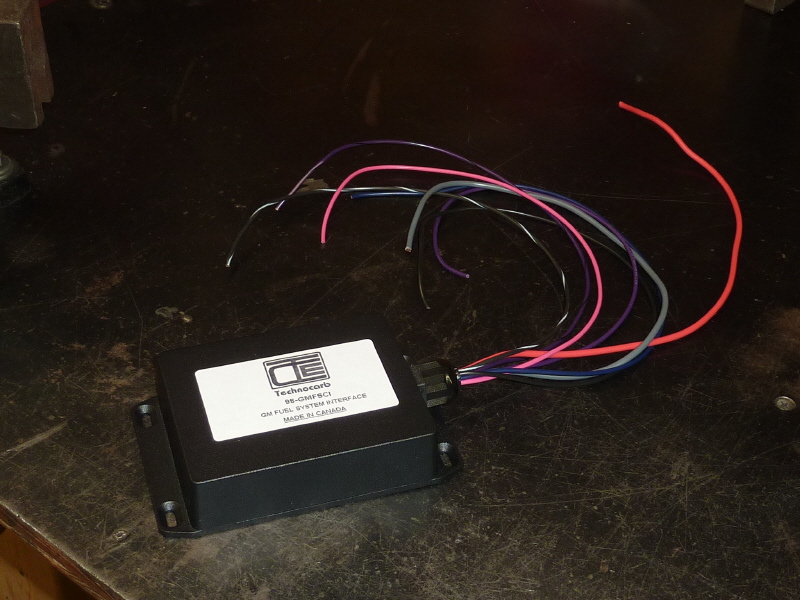

This is the GM Fuel System Controller Interface or "98-GMFSCI". This device prevents the gasoline fuel rail pressure from exceeding factory limits, while running on CNG.

|

Here I am laying out the bracket base on a piece of 4" x 1/4" bar.

The 1/4" bar is over kill, however the bracket will be extremely rigid and vibration proof. |

Next the bar is chucked in the band saw and cut to length. A metal cutting band saw is a must. It just makes life easy.

|

With the base cut and the corners rounded, the mount holes are transferred to the bracket.

|

They are then drilled and tapped to accept a 1/4x20 bolt.

|

Next a mounting flange is cut and the corners rounded. It is pre fitted to the base bracket for clearance and alignment. |

I had decided to mount the bracket off the CNG tank support backing plate. Here I am removing two bolts from the top of the support.

|

From the bottom side the location is perfect. |

Next the flange bolt hole locations are transferred to masking tape. |

Then the hole locations are transferred to the mounting flange and center punched. |

The mounting holes are drilled and de-burred.

|

Next the mounting flange and base bracket are clamped up and TIG welded on this side only. |

The bracket is flipped over and DC stick welded on the other side. I use a 7024 rod for most stick welding. The 7024 produces a quality weld and deposits a lot of weld metal in the joint.

|

Here the bracket is back from the sand blasting booth. I use an 80 grit aluminum oxide media Instead of sand. It cuts the blasting time by a factor 8. |

Since this bracket is exposed to the elements, 4 coats of Satin Rustoleum are applied. |

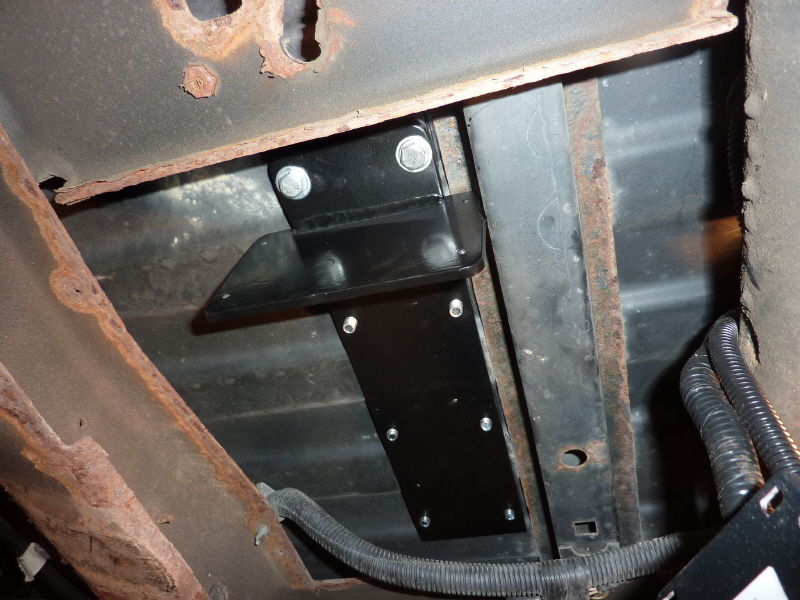

The bracket is bolted in place and final clearance is checked. |

Another view if the bracket. You can see the OEM gasoline fuel interface to the left of the picture.

|

This was another easy, no brainier bracket to make. Wish they all were this way. |