The conical bottom is a 60° angle from the cylinder wall. The slope is

just the right angle so the trub, dead yeast cells, and everything falling

out of suspension will slide to the bottom at the apex of the cone. The trub

can be drained with a minimum waste of good beer. No siphion is needed when

racking as the side port is always below the bier line.

I started out with a piece of 1 1/2"

x 3/16" x 6' steel bar bent around

a 3/4" plywood form the diameter of

the fermentor. I then opened my vice

6 inches and layed the semi round

ring across the opening. Hammering

and rotating the ring, at the center

of the vice, until it was close to

the plywood form.

|

The semi ring was measured, cut and

welded together to form a complete ring.

At this point the ring was slid over

the fermentor. Then the high and low

spots were hammered out on the vice

until the ring slid over and down to

the lid opening with no binding.

|

To cut costs, I used 1/2" electrical

conduit to make the legs and support

trusses. Each leg was notched and

flattened slightly to clear the

fermentor body.

|

Each leg was clamped and trued vertical

before being welded at 120 degrees

apart around the ring.

|

The fermentor was then slid down into the

emerging stand and dimensionally checked

for clearance and fit.

|

Once proper fit was established it was

time to fabricate the support trusses.

Three pieces of 1/2" electrical conduit

were cut to rough fit. With the help of

a 5/8" bi-metal hole saw chucked into a

drill press, I cut each support truss

to form half moon ends.

|

Two cut per end were needed to make the

ends match up nice and snug. A little

de-burring and filing cleaned things

up for welding.

|

The support trusses were then fitted on

the vertical legs, leveled and tied off

with binders twine to hold them in place.

Each truss is tack welded in preperation

for the final weldng.

|

Once the tack welding is done, the stand

is then transfered to the vice for final

welding. In the vice, it can be repositioned

in any angle for the best access. Note the

Becks Dark in the backround. My inspiration

for this entire project.

|

Here is a look with the hopper body

dropped into the welded stand. It nice

when a plan comes together.

|

The next task at hand are the tabs

that hold the clamping bar to the stand.

I used a left over piece of the ring to

make the tabs. There is nothing like a

1/8" full flow electrode at 175 amps to

lay down the near perfect bead.

|

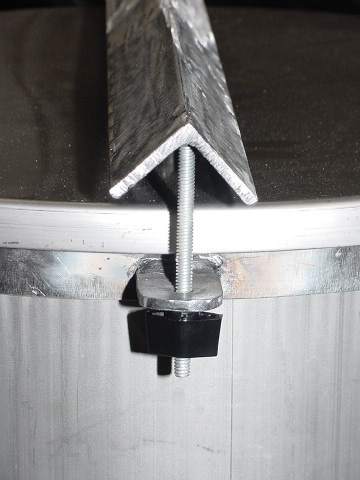

The clamping bar is made from a piece

1 1/2" x 3/16" angle. A 1/4-20 threaded

connector is welded at the center for

the one of the leg pads to seat against

the top of the lid.

|

At each end of the clamping bar a hole

is drilled and taped. 1/4-20 thread all

is then screwed in and adjusted to height,

cut and tack welded from the top. Note the

thumb nut to adjust the clamping pressure.

|

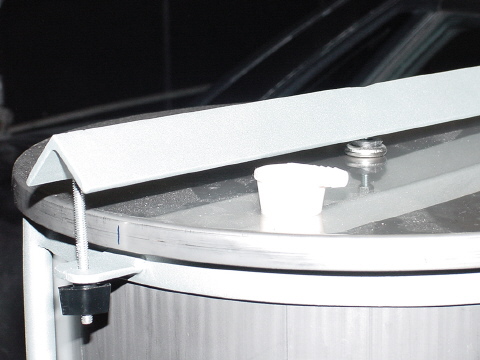

A view of the clamping bar in place. At

the bottom of each leg is a 1/4-20 nut,

fitted into the end and welded. This

provides the leg pads something to

screw into.

|

Here is a view of the stand after two

coats of primer and two coats of

texture paint.

|

Here two aluminum plates are cut,

drilled for the 7/16" grommets

and pop rivited in place. If you

struggle for head space in the

refrigerator/lagering cabinet,

the air lock can be transfered

down here.

|

Here is a view of the Rubber stopper.

A 1 1/4" bi-metal hole saw was used to

cut the hole. The lid was clamped onto

the drill press table and lots of water

was used to cool the hole saw.

|

An Assembled view

|

Another assembled view

|